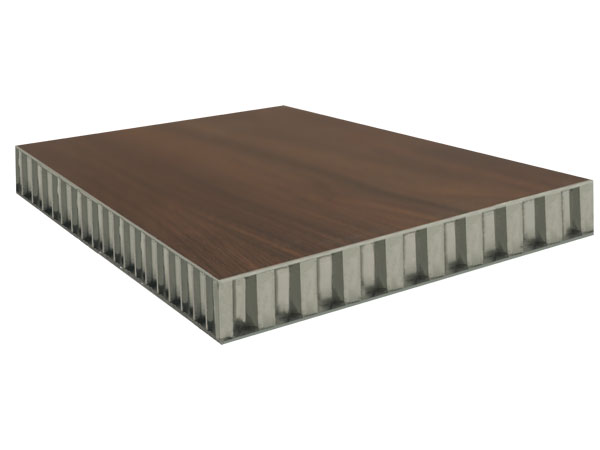

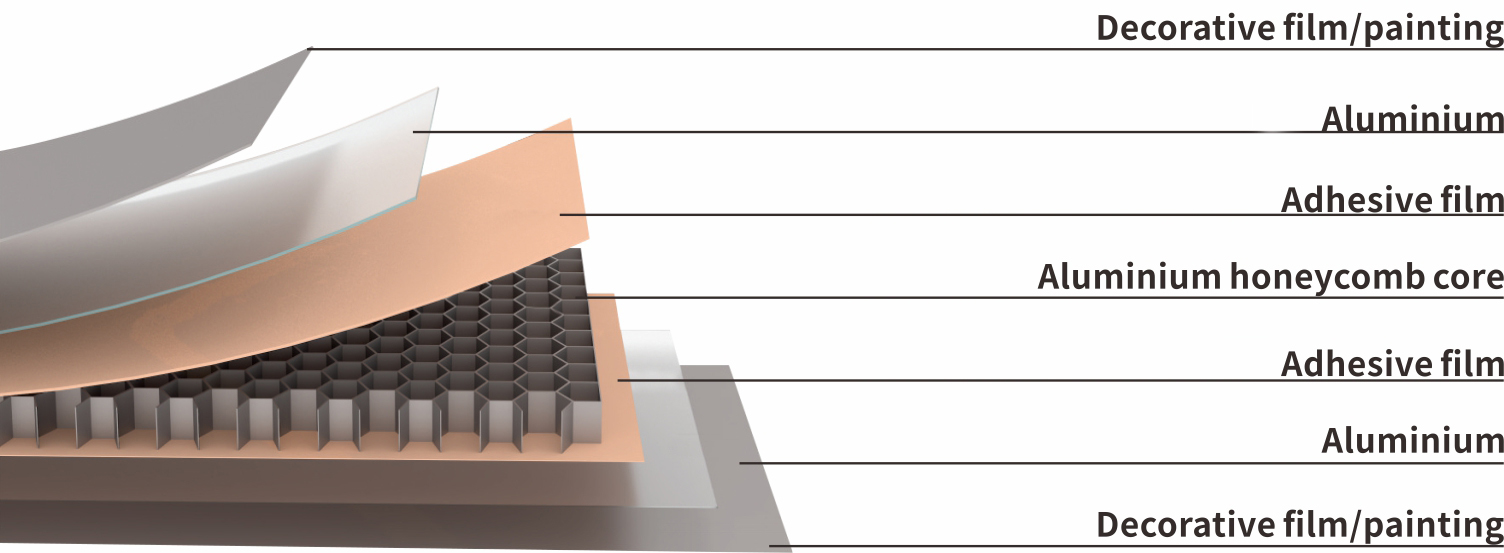

Total thickness:

6-25mm CustomizableAluminum thickness:

0.7-0.8mm CustomizableHoneycomb Core Shape:

Six DeformationsIntro:

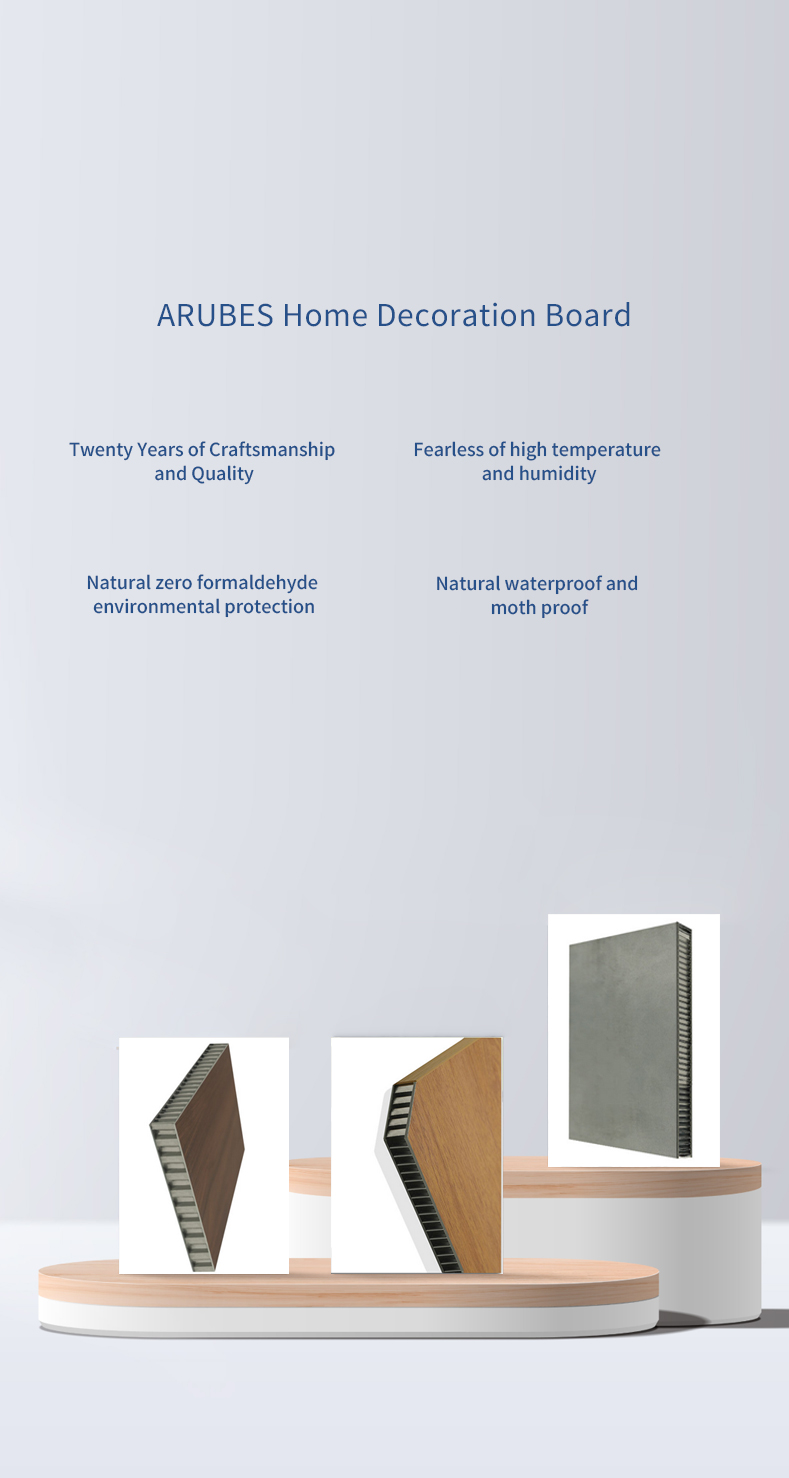

The design idea of ARUBES Aluminium Honeycomb Panel comes from the I-beam structure. The panels on both sides are high-strength aluminium panels, and the inner layer is a special hexagonal aluminium honeycomb. The Arubes aluminium Honeycomb panel has light weight, good rigidity, high bending strength, high shear strength, good stability, and good seismic, heat insulation, sound insulation and other properties.

Different noble and modern fashion furniture organic integration, generous shape, highlight quality and luxury, reflect the user's unique insight and have refined taste and style.

Technical Index

Test item | Unit | Aluminium Honeycomb Panel Index 18mm0.7/0.7 |

Maximum Load-bearing Load | KN/m2 | ≥ 3.4 |

Proportion | g/cm3 | 5.0 |

Drum Peel Strength | N·mm /mm | ≥ 110 |

Flat Crush Strength | MPa | ≥ 1.5 |

Flat Crush Elastic Modulus | MPa | ≥ 45 |

Plane Shear Strength | MPa | ≥ 0.7 |

Plane Shear Elastic Modulus | MPa | ≥ 6.0 |

The Bending Stiffness | N·mm | ≥ 7.0 ×108 |

Shear Stiffness | N | ≥ 1.5 ×104 |

Impact Resistance | / | No obvious deformation or damage |

Boiling Water Resistance | / | no abnormity |

Side Length | mm | ±2 |

Thickness | mm | ±0.2 |

Diagonal Length Difference | mm | ≤ 3 |

Edge Straightness | mm/m | ≤ 2 |

Smoothness | mm/m | ≤ 2 |

Safety Performance

Test item | Unit | Aluminium Honeycomb Panel Index |

Formaldehyde Content | Mg/m3 | Not Detected |

Burning Behavior | B1 | Safely Applicable |

Product Comparison Table

Performance | Wood type board | Aluminum-plastic composite board | Aluminium veneer | ARUBES Galvanized Steel Honeycomb Panel | ARUBES Aluminium Honeycomb Panel | ARUBES Multi-layer Honeycomb Panel |

Structure | Solid Wood Construction | Sandwich Structure | Aluminum Construction | Steel Aluminum Structure | Aluminum Construction | Multilayer Structure |

Durability | ★★★ | ★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Environmental Protection Index | ★★ | ★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Surface Material | ★ | ★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Water Repellency | ★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Color Uniformity | ★ | ★★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Structural Safety | ★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Product Weight | ★★★ | ★★ | ★ | ★★★★ | ★★★★★ | ★★★★★ |

Machinability | ★★★★★ | ★★★★★ | ★ | ★★★★★ | ★★★★★ | ★★★★★ |

Deformation resistance to wind pressure | ★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Heat preservation and insulation | ★★★★ | ★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

Sound insulation and noise reduction | ★★★ | ★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ |